Cryogenic Pob Valve Ob Chav Thaiv thiab Bleed -196C Cryogenic Service

Lub pob valve ob chav thaiv thiab los ntshav yog DBB pob valve rau cov kev pabcuam cryogenic ua haujlwm.

Nws muaj cov qauv kev cog lus rau tsim ob lub pob hauv lub koom haum lub cev, xav tau qhov chaw sib dhos tsawg dua, tib lub sijhawm thiab txaus siab rau ob qhov kev cais tawm hauv cov txheej txheem tshwj xeeb rau kev tswj hwm kev nyab xeeb.Piv nrog rau ntau lub valve sib txuas ua ke, lub valve no ua haujlwm zoo dua.

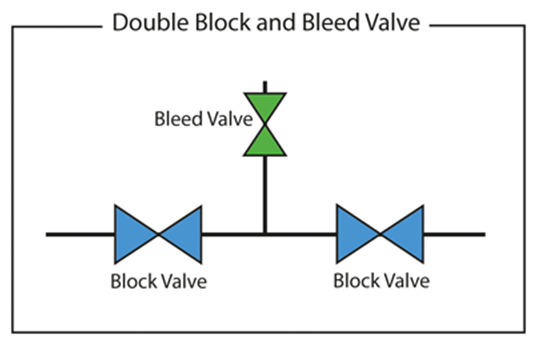

DBB pob li qub muab los ntawm cov dej ntws mus rau hauv qab xoom xoom kev ua haujlwm.Lub valve no tuaj yeem cais cov kav dej ntawm ob sab ntawm lub valve kom tso pa tawm lossis los ntshav cov kab noj hniav ntawm lub rooj zaum.Nws yog siv nyob rau hauv kev sib cais tseem ceeb nyob rau hauv ntau yam kev siv thiab kev lag luam, xws li liquefied natural gas, petrochemical kev lag luam, kis tau tus mob thiab cia, natural gas industrial processes, lub ntsiab thiab manifold li qub nyob rau hauv cov kua pipelines, thiab refined khoom kis tau tus mob pipelines.

● Kev pabcuam Cryogenic -196 ℃

● Peb li qub hauv ib lub cev compact

● Tsawg xau point Tsawg qhov chaw teeb tsa

● Tso cai rau kev ruaj ntseg ntawm lub rooj sib khi

● Tiv thaiv kom txhob muaj kab mob

Fig. ob chav thaiv thiab los ntshav valve system

ARAN muaj ntau yam ntawm DBB valve hom thiab cov kev xaiv kom haum rau cov kev xav tau tshwj xeeb, cov khoom siv valve / xaus / kev pabcuam txhua tus tuaj yeem hloov kho.Koj muaj cov lus qhia rau peb tus kws tshaj lij kev muag khoom los xaiv tus qauv raug rau koj.

Daim ntawv thov

ARAN Cryogenic pob li qub tau tsim nyob rau hauv kev ua tau zoo tshaj plaws thiab ua tau zoo tshaj plaws, tuaj yeem ua tau raws li cov txheej txheem siab tshaj plaws cryogenic, thiab wildly thov rau kev nyab xeeb kev thauj mus los rau kev ua, khaws cia, xa khoom thiab xa tawm ntawm ethylene, Kua Nitrogen, Oxygen, LPG, Liquefied Natural Gas ( LNG) thiab lwm yam uas tsis muaj dej kub liquefied gases.

Raws li lub zog huv huv thiab ruaj khov, LNG tau qhia txog kev loj hlob dav dav hauv txhua yam ntawm cov saw hlau.Cryogenic pob valve yog qhov xav tau tshaj plaws hauv cov kua dej cryogenic thiab cov khoom siv thauj mus los.Nws muaj qhov zoo ntawm kev hloov pauv hloov pauv, txhim khu kev qha sealing, kev nyab xeeb thiab ruaj khov thiab lwm yam.

Crygenic Treatment Thiab Test

Lub valve qhov chaw rau cov kev pabcuam cryogenic xav tau kev kho cryogenic kom paub tseeb tias cov khoom siv valve yuav haum rau qhov kub thiab txias.

Txoj kev kho cryogenic yog cov txheej txheem ntawm kev tso lub valve rau qhov kub thiab txias los ntawm nruab nrab nitrogen -196 ℃ txhawm rau tshem tawm cov kev ntxhov siab thiab txhim kho kev hnav tsis kam hauv cov hlau.

ARAN cryogenic kho rau pob valve ib feem thiab cryogenic kuaj rau tiav valve.

| Ntau yam | Cryogenic pob valve ob chav thaiv thiab los ntshav |

| Loj | NPS 1/2 "~ 8" (50mm ~ 200mm) |

| Siab | ASME Chav Kawm 150 ~ 600LBS (PN16 ~ PN100) |

| Cov qauv tsim khoom | API/ANSI/ASME/EN/DIN/BS/GB/GOST |

| Tsim & MFG code | BS6364 / SHELL SPE 770200 Tsis tshua muaj kub valve API 6D / ASME B16.34 / ISO17292 / ISO 14313 / BS5351 |

| Ntsej muag ntsej muag | ASME B16.10, EN558 |

| Xaus kev sib txuas | Flange RF / RTJ ASME B16.5 / EN1092-1 / GOST 33259 ; KUB WELD BW ASME B16.25 |

| Kuaj & Tshawb xyuas | TS EN ISO 15848 / SHELL SPE 77/312 Kev ntsuas kub qis qis API 598, API 6D, ISO 5208 / ISO 5208 / EN12266 / GOST 9544 |

| Khoom siv code | Cov pa roj carbon monoxide qis -40 ℃ (ASTM A350 LF2 / LF3, ASTM A352 LCB / LCC) Tsawg Kub Carbon Steel -101 ℃ (ASTM A350 LF3, ASTM A352 LC3) Stainless hlau -196 ℃ (ASTM A182 F316 / F316) F304L Dual Qib, ASTM A351 CF8M / CF3M, CF8 / CF3) |

| Kev ua haujlwm | Los ntawm txhais tes, Worm Gearbox, Pneumatic actuator, Hluav taws xob actuator, Hydraulic-electric actuator |

| Tsim tshwj xeeb | Cryogenic pob li qub |

| Tsis tshua muaj kub mus rau -196℃ | |

| Extend bonnet rau txhim khu kev qha packing thiab sealing, ntxiv qia ntev acc.mus rau qhov kub thiab txias | |

| Nthuav qia nrog drip pallet tsim acc.mus rau qhov kub thiab txias | |

| API6 24 Tsawg khiav tawm emission packing | |

| Nyob load API 622 graphite | |

| Lub cev kab noj hniav siab nyem system | |

| Floating pob hom ib txoj kev sealing | |

| Trunnion pob hom Ob chav cais thiab thaiv, bidirectional sealing | |

| Basic tsim | pob li qub |

| THAUM TSEEM CEEB | API 607 Cov |

| ANTI STATICS | API 608 |

| Stem feature | Anti tshuab tawm pov thawj |

| Kev tsim kho Bonnet | Bolted lub kaus mom |

| Pob hom | Sab nkag los yog ob chav thaiv & cov pob los ntshav |

| Hom tho txawv | Full bore los yog Reduced Bore |

| Optional customize | NACE MR0175, MR0103, ISO 15156 ua raws |

| ISO 5211 MOUNTING PAD Npuag ncej | |

| Limit Hloov | |

| Xauv ntaus ntawv | |

| ESDV kev pabcuam tsim nyog | |

| TS EN ISO 15848-1 thiab ISO 15848-1 Kev sim ntsuas qis qis qis | |

| Tsis-destructive test (NDT) API 6D, ASME B16.34 | |

| Daim ntawv tshaj tawm kev soj ntsuam thib peb | |

| Cov ntaub ntawv | EN 10204 3.1 MTR Cov ntaub ntawv xeem cov ntaub ntawv |

| Kev tshuaj ntsuam xyuas siab | |

| Daim ntawv qhia txog kev pom thiab qhov ntev | |

| Khoom warranty | |

| Valve kev ua haujlwm phau ntawv |